A325 and A490 bolts are household names. What are F1852 and F2280?

ASTM A325 AND A490 BOLTS are the high-strength bolts used for structural applications in North America. Their twist-off type counterparts are F1852 and F2280, respectively (Figure 1). ASTM standards A325M and A490M cover the metric versions (although metric bolts are rare). Generally, bolt standards are introduced when new products become available and the demand exists. ASTM Standards A325 and A490 have been around for half a century, whereas A325M, A490M, F1852, and F2280 were released in later dates. All six standards include many provisions that are common to two or more standards as well as provisions that are unique to one. Recently, ASTM saw the need and opportunity to streamline the process and moved to consolidate these standards.

ASTM STANDARD F3125

ASTM F3125, a consolidation and replacement of six standards, A325, A325M, A490, A490M, F1852, and F2280, published in January 2015. The consolidation aims to simplify revisions in the future. It may also enhance user-friendliness by eliminating duplication of provisions that are common to all bolt grades, types, styles, etc. Unlike other bolt standards, F3125 was not issued to cover a new product. In this umbrella standard, the name of each bolt standard becomes a bolt grade (e.g. A490 becomes F3125 Grade A490). The traditional bolt type designations remain (i.e. Type 3 for weathering steel and Type 1 for bolts of other high-strength steel compositions). There are two bolt styles: F1852 and F2280 are referred to as “twist-off style” bolts, while the others are Heavy Hex Style bolts.

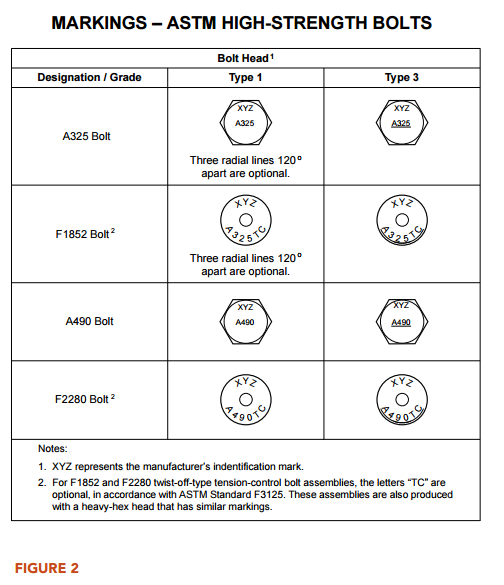

All bolts manufactured after the publication date of F3125 in January 2015 must comply with the marking requirements of F3125. In an attempt to orchestrate a smooth transition, bolt head markings remain essentially unchanged, as shown in Figure 2. In addition, technical changes have been kept to the minimum.

A notable change is the increase in unit tensile strength: Fu, for A325 and F1852 bolts, 11/8-inch in diameter and larger, to 120 ksi (825 MPa). This change unifies the unit tensile strength level for these bolts irrespective of diameter. Provisions for 1¼-inch F1852 bolts have also been incorporated in F3125. Other changes include an addition of ductility requirements for twist-off style bolts, more detailed rotational capacity test requirements, and an annex for coatings.

The above-mentioned increase in tensile strength generally affects the design of connections having large diameter A325 and F1852 bolts. These bolts are not commonly used in construction of buildings and bridges although users may resort to A325 bolts when strong galvanized bolts are required (A490 and F2280 bolts should not be galvanized or plated and F1852 bolts should be not be hot-dip galvanized). Both the tensile and shear resistance of these bolts increase with the tensile strength increase. The slip resistance (for a given class of contact surface and installation method) increases with the pretensioned force, which is proportional to the ultimate tensile strength.

While new bolts must comply with F3125, 11/8-inch F1852 bolts in the old inventory were made and calibrated to twist off at a pretensioned force based on the lower tensile strength (105 ksi instead of 120 ksi). Ignoring the strength increase in large A325 and F1852 bolts is a safe and conservative interim solution.

CSA S16-14

S16-14 adopted the tensile strength, Fu, and minimum pretension forces for bolts in ASTM bolt standards prior to publication of F3125 and values for Fu are explicitly stated in S16-14 Standard. Therefore, the strength increase in large A325 and F1852 bolts does not affect designs in accordance with S16-14.

CSA S6-14

Since the vast majority of bolts used for bridge construction are 7/8-inch and 1-inch diameter bolts their resistances are not affected by the strength increase in larger bolts. When use of larger A325 and F1852 bolts is contemplated this is the situation: Contrary to S16, CSA S6 does not state the values for Fu but defines Fu to be the specified ultimate tensile strength of the bolt material and pretensioned bolts be tightened to at least 70% of Fu. Hence the strength increase may be accounted for in the design when use of bolts manufactured to F3125 is confirmed whereas ignoring the higher strength is a safe and conservative interim solution.