Steel: The world’s most sustainable building material

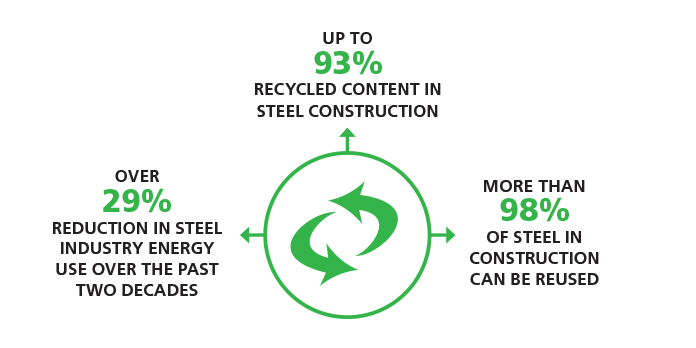

Steel’s inherent green attributes, performance features, and its cradle-to-grave life cycle make it one of the most sustainable construction materials on the planet.

The steel industry has significantly reduced its environmental footprint at every stage of the construction process from raw material extraction and manufacturing to fabrication and erection on job sites.

Why does Steel as a Recycled Product Matter ?

As seen in the graphic, construction steels (beams for example) manufactured in North America are primarily made from recycled steels using the electric arc furnace process (EAF). The EAF process is approximately 4x lower in embodied carbon than the older blast oxygen furnace (BOF) process of making steel. Some steel sheet and plate products are still produced with blast oxygen furnaces in North America but that is rapidly changing. Ontario steel mills for example are in the process of upgrading to advanced modern low carbon BOF mills and to new EAF mills dramatically cutting carbon emissions in their steel production. It is estimated that when complete, the two mills in Ontario will cut their combined carbon emissions equivalent to the emissions of 12 million cars per year.

So by recycling, we get the best building product in the world at extremely low carbon values. Also by recycling, we cut the need to mine new iron and coal conserving the environment as well as energy.

Reuse and the Circular Economy

The reuse of steel in North America is probably the industry’s best-kept secret. As a building nears the end of its life, steel from that building can be reused either through the reuse of elements for another building project, the reuse of the steel structure in situ (which may include a structural design upgrade), or the dismantling and reuse of the structure at another location. Seen as the ultimate method to achieve the lowest embodied carbon in a building, the supply infrastructure and design awareness of these low carbon building opportunities are only now being explored.

An example is the renovation of Triffo Hall on the University of Alberta campus, which typifies the adage that what was old, is new again. Built primarily of steel in 1915, it is the first project at the University to be registered with LEED. The new design features a two-storey interior “street”, that reused and expressed the steel trusses which run the length of the building along the brick wall. Punctures through the second floor allow this “street” to be flooded with natural light. Reusing a steel structure is often easier than one thinks.

Beyond recycled content and reuse, steel works well with other materials. It has several attributes that make it a suitable choice for a sustainable solution. So many people like a steel-built environment because it is light, open, airy and adaptable. Steel structures mature well with age, rather than deteriorate and decay. Steel’s long clear spans mean that interiors can be changed with ease. Steel frames can readily be adapted and reconfigured to give old buildings a new lease on life, economically and efficiently. The longevity of a building is fundamental to its overall sustainability.

Sustainable Steel Construction

Sustainable Fabrication and Construction

- Structural steel is fabricated regionally in off-site facilities reducing construction periods by 60%.

- Minimal waste is generated at fabrication facilities and construction sites.

- Any waste generated is fully recyclable and resalable.

- Centralized, off-site fabrication reduces number of on-site workers by 75%.

- Modern fabrication technology provides greater precision, productivity, and safety.

- Steel members are efficiently transported by truck, rail, or barge.

Sustainable Projects

- Steel buildings are easily deconstructed, enabling reuse of the steel members.

- Steel-framed buildings are highly durable and have a long life span.

- Steel reduces the building weight and footprint by accommodating longer spans with smaller member sections.

- Steel framing allows easy integration of mechanical systems, resulting in low floor-to-floor heights, less building volume, and lower energy consumption.

- Steel framing systems allow for large window areas, resulting in plentiful natural lighting, higher occupant comfort, and reduced electrical consumption.

- Established high demand for steel scrap ensures future reuse/recycling of a steel building frame.

- Minimal ongoing maintenance is required.